Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

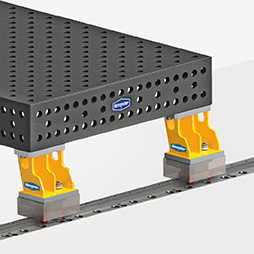

Demmeler tool changeover systems stand for power, efficiency and dynamics

Demmeler’s patented robot-based tool changeover system has been among the most popular tool storage and changeover systems for large-scale machines on the market for many years. Our tool changeover systems come into play when requriements for large numbers of tools and high tool weights with simultaneous great flexibility have to be met.

The Demmeler systems can hold up to 750 different tools and make them available in record time. Tools are automatically inspected as part of the process and a replacement is initiated when needed. Freely programmable PC-based systems ensure extensive adaptability to various machine control systems. As high-end solutions with linear axis and head change units, these systems meet the requirements of even the largest processing centres and the most complex production processes. For machines of medium size, we supply the proven system as a modified compact arena.

The Demmeler Tool Rack adapts to your machine!

- A high tool density is achieved with a gripper column that can rotate more than 180°. This also makes the space behind the column usable.

- Rack shape can be perfectly adapted to the machine conditions.

- Highly compact design thanks to interior drive and guides.

- Tool spacing from slot to slot 140 mm.

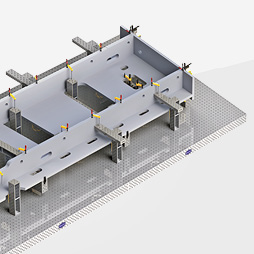

Tool Arena with Linear Axis

Application

Fast changing and measuring of tools with weight up to 100 kg and 1.500 mm length

Characteristic Tool Arena

- Traversing distance 5.000 mm

- Traversing speed 80 m/min

- Capacity 450 tools

- 2 x 5 set-up stations

- Proportional gripper

- Complete roof

Linear Arena

Application

Fast changing and measuring of tools with weight up to 100 kg and 1.000 mm length

Characteristic Tool Arena

- Small space requirement – distance from segment to mid of linear axis approx. 1.600 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- 2 x 8 setup stations

- Standard gripper

Compact Arena / Single-row Version

Application

Fast changing and measuring of tools with weight up to 40 kg and 800 mm length

Characteristic Compact Arena

- Small space requirement – radius of segments approx. 1.750 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- Standard gripper

- Can be delivered in one piece

Robot grippers

Application

Gripping and handling of tools with weight up to 100 kg and 1.500 mm length

1 Characteristic proportional gripper

- Gripping area of 97,5 to 221 mm

- Integrated measuring system enables an optimum opening stroke of the claws for best tool distances in the rack

- Max. tool diameter of up to 450 mm

- Gripping lock in case of pressure drop is integrated

2 Characteristic cone gripper

- Gripping the tool at the cone; that allows to transfer the tool to a supply unit into the machine via the gripping slot

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

3 Characteristic standard gripper

- Gripping area of 97,5 to 128 mm

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

Easy Handling

Characteristic Controller Unit

- Tool management with a very convenient graphical interface

- High machine availability due to an intelligent roboter control with priority management

- Storage and retrieval during machining process

- Automatic space optimized storage system ensures high tool density

- Damaged tool strategy

- Sister tool strategy

- A flexible change moment ensures optimum processing rates

- Identification of tools via RFID chip