Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Machinery – Precision and power on 20,000 square metres

We are firmly convinced that we can only persist as an innovation and quality leader if we consistently focus on two points. Delivering the best quality requires highly motivated employees with excellent technical skills and extensive creative freedom as well as a highly innovative train of machines.

We fabricate our products with the following machine types in various dimensions, among others: Travelling column milling machines, Gantry milling machines, Horizontal centres, Lathes, Processing centres. As experts in the fields of mechanical engineering and automation technology, we also pursue the continuous further development of existing systems in our manufacturing sector. We have already realised a variety of fixtures, delivery systems and machine adaptations for the continuous optimisation of processes and quality. If you stop getting better, you stop being good.

Our extensive machine park

| Traverse paths: | X 26,000 mm / Y 7,000 mm / Z 1,900 mm |

| Rotary table: | Ø 4,300 mm / Interference area: 8,000 mm / 80 U/min |

| Spindle performance: | 100 kW |

| Interchangeable heads: | 4 |

| Tool places: | 150 |

| Traverse paths: | 2 X 5,000 mm (alternating operation) / X 10,000 mm (single operation) / Y 3,000 mm / Z 1,500 mm |

| Spindle performance: | 45 kW |

| Number of pallets: | 2 |

| Interchangeable heads: | 3 |

| Aggregates: | Station with 5 slots |

| Tool places: | DEMMELER tool arena with 240 slots HSK100 |

| Others: | 2 clamping tables (4,000 mm x 2,500 mm) |

| Traverse paths: | X 5,500 mm Y 3,000 mm Z 1,500 mm |

| Spindle performance: | 40 kW |

| Interchangeable head: | Automatic milling head changeover (vertical/horizontal) > 5-side processing |

| Tool places: | 180x tool changer with SK50 |

| Distance between uprights: | 3,000 mm |

| Traverse paths: | X 5,500 mm Y 2,750 mm Z 1,250 mm |

| Spindle performance: | 35 kW |

| Interchangeable head: | Automatic milling head changeover (vertical/horizontal) > 5-side processing |

| Tool places: | DEMMELER tool arena with 300 slots HSK 50 |

| Distance between uprights: | 2,750 mm |

| Traverse paths: | X 11,500 mm / 5,500 mm with single table Y 4,500 mm Z 1,500 mm |

| Spindle performance: | 80 kW |

| Tool places: | 280x tool changer with HSK100 up to collar ø 125 |

| Interchangeable head: | Automatic milling head changeover (vertical/horizontal) > 5-side processing and c-axis |

| Distance between uprights: | 3,050 mm |

| Dualtable systems: | 2 tables 4,000 x 2,500 mm |

| Traverse paths: | X 10,580 mm / 5,060 mm with single table Y 4,000 mm Z 1,500 mm |

| Spindle performance: | 93 kW |

| Tool places: | 311x tool changer with HSK100 up to collar ø 125 |

| Interchangeable head: | Automatic milling head changeover (vertical/horizontal) > 5-side processing and c-axis |

| Distance between uprights: | 3,050 mm |

| Dualtable systems: | 2 tables 4,000 x 2,500 mm |

| Traverse paths: | X 10,580 mm / 5,060 mm with single table Y 4,000 mm Z 1,500 mm |

| Spindle performance: | 93 kW |

| Tool places: | 311x tool changer with HSK100 up to collar ø 125 |

| Interchangeable head: | Automatic milling head changeover (vertical/horizontal) > 5-side processing and c-axis |

| Distance between uprights: | 3,050 mm |

| Dualtable systems: | 2 tables 4,000 x 2,500 mm |

| Traverse paths: | X 12,000 mm Y 3,100 mm Z 1,300 mm |

| Rotary table: | 2,200 x 2,200 mm / 25 tons load capacity as additional axis |

| Spindle performance: | 50 kW |

| Universal head: | for 5-sided processing |

| Tool places: | 160 / HSK 100 |

| Traverse paths: | X 12,000 mm Y 2,100 mm Z 1,300 mm |

| Spindle performance: | 41 kW |

| Universal head: | for 5-sided processing |

| Tool places: | 120 / HSK 100 |

| Milling length: | 3,500 mm |

| Milling path: | Y-axis 1,400 mm Z-axis 1,200 mm |

| Spindle performance: | 30 kW |

| Pallets: | 2 Pallet changeover |

| Universal head: | for 5-sided processing |

| Tool places: | 200 / SK50 |

| Traverse paths: | X 1,800 mm Y 2,000 mm Z 1,100 mm |

| Spindle performance: | 40 kW / 10,000 U/min |

| Pallets: | 2x pallet changing system: 2x pallet size 1,600 x 1,200 mm / Interference area 2,500 mm |

| Tool places: | 120 / SK50 |

| 5-sided processing and spatial processing possible due to the 5 axes |

| Machine 1 | |

| Traverse paths: | X 1,050 mm Y 800 mm Z 880 mm |

| Spindle performance: | 40 kW / 10,000 min-1 |

| Tool places: | 240x tool changer with SK50 |

| Machine 2 | |

| Traverse paths: | X 1,050 mm Y 800 mm Z 880 mm |

| Spindle performance: | 40 kW / 10,000 min-1 |

| Tool places: | 80x tool changer with SK50 |

| Machine 3 | Pallet changing system |

| Pallet size: | 630 x 630 mm / 800 x 630 mm |

| Pallets: | 30x Pallet changeover |

| Traverse paths: | X 1,050 mm Y 800 mm Z 880 mm |

| Spindle performance: | 40 kW / 10,000 min-1, 1,200 Nm torque |

| Pallets: | 2x Pallet changeover |

| Pallet size: | 630 x 630 mm / 800 x 630 mm |

| Tool places: | 80x tool changer with SK50 |

| Max. part length: | 1,500 mm |

| Max. turning diameter: | 500 mm |

| Max. speed: | up to 4,000 U/min |

| Tool places: | 49 |

| Traverse paths: | X 560 mm Y 560 mm Z 510 mm |

| Spindle performance: | 22 kW |

| Paletts: | 2 |

| Tool places: | 40 |

| Max. turning diameter: | 65 mm |

| Max. part length: | 150 mm |

| Max. speed: | up to 5,000 U/min |

| Tool places: | 36 |

| Max. part length: | 1,150 mm |

| Max. turning diameter: | 450 mm |

| Max. speed: | up to 3,500 U/min |

| Tool places: | 12 |

| Max. part length: | 150 mm |

| Max. turning diameter: | 65 mm |

| Max. speed: | up tp 7,000 U/min |

| Tool places: | 24 |

| Max. part length: | 150 mm |

| Max. turning diameter: | 40 mm |

| Max. speed: | up to 7,000 U/min |

| Tool places: | 24 |

| Traverse paths: | X 500 mm Y 450 mm Z 400 mm |

| Spindle performance: | 13 kW |

| Number of pallets: | 1 |

| Tool places: | 30 |

| Traverse paths: | X 900 mm Y 950 mm Z 930 mm |

| Spindle performance: | 46 kW |

| Number of pallets: | 1 |

| Tool places: | 100 HSK 100 |

| Traverse paths: | X 500 mm Y 400 mm Z 400 mm |

| Spindle performance: | 13 kW |

| Number of pallets: | 1 |

| Tool places: | 16 |

| Traverse paths: | X 600 mm Y 600 mm Z 600 mm |

| Spindle performance: | 28 kW |

| Number of pallets: | 2 |

| Tool places: | 120 |

Synchronous welding of both robots on one work piece is possible. Traverse path: 16,000 mm.

Steel construction

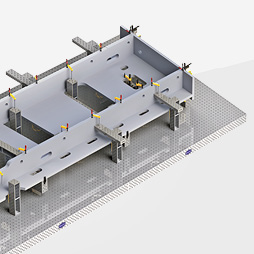

Welding requires the highest precision and qualification. That's why certified welders according to DIN EN ISO 9606-1 / 2 are a matter of course for DEMMELER. Our spacious manufacturing halls, crane systems of various sizes and state-of-the-art welding equipment including robot welding ensure high-quality and effective processing.

From individual parts and small series to large assemblies, the production with a wide variety of materials is possible.

Steel construction

Welding stations

| Manual welding stations |

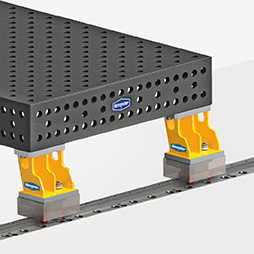

| Original DEMMELER 3D clamping system with accessories |

| DEMMELER Manipulator M8000 |

| DEMMELER Manipulator LP8000 |

| Powerful welding equipment |

Steel construction

CLOOS robot welding system

| 2 welding robot Qirox QRC 350 |

| Longitudinal cross-height carriage system for 2 robots Traverse paths: 16,000 mm / 2,500 mm / 1,500 mm, Max. collision circle: 5 m, 21 axes |

| Synchronous welding of both robots on one work piece |

| Position detection of the work pieces by means of laser sensors |

| 2 L-manipulators: single load 5 tons, as a counter bearing 10 tons height adjustable |

Quality assurance in the air-conditioned compartment

In addition to a corresponding layout, the best base materials and excellence in production, DEMMELER guarantees the best quality in the market through quality assurance equipped among other things with 3D coordinate measuring machines and optical measuring instruments. Naturally inspections and measurements are performed in air-conditioned measuring rooms in order to ensure that the corresponding tolerances are met.

ZEISS bridge-type measuring machine

| Measuring path: | X 3,000 mm Y 2,500 mm Z 2,000 mm |

| Loading axis: | 3,000 mm traverse path |

| Automated probe changer |

CNC coordinate measuring machine Brown & Sharp

| Measuring path: | X 2,200 mm Y 1,200 mm Z 1,200 mm |

| Granite plate: | 3,170 x 1,400 mm |

| Automated probe change |

Granite plate

| Size: | 5,500 x 2,000 mm |

| Measurement columns: | 1,200 mm (resolution 0,001) |

Autocollimator

| Nivelltronic |

| Levelltronic |