Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

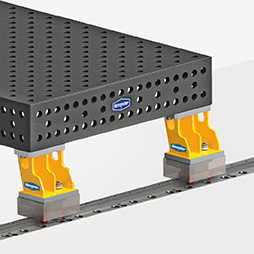

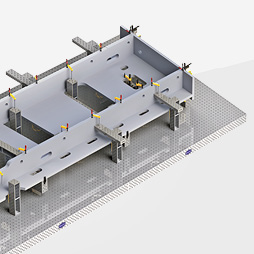

DEMMELER base rails – for big projects!

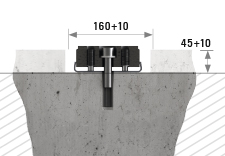

Our flexible clamping system grows with your tasks. The modular structure of the base rail system offers you the greatest possible freedom for the production of bigger than normal components. A grid system of any size adapted to your product portfolio can be installed in your production hall. This provides you with a level installation surface over the entire area, including grid bores. The rail system is installed according to your requirements. Several versions are available to you, for example overfloor or underfloor installation. The advantage of underfloor installation is that the entire work area around the rail system is accessible for persons and vehicles.

Rail system

-

Support and base rail

Bearing load per metre up to 16 tons, precise positioning with D28 bores in a 100 mm grid

Price on requestplus VAT

-

Support and base rail XL

Bearing load per metre up to 30 tons, suitable for very heavy-duty and all standard applications

Price on requestplus VAT

-

Support and base rail LINEAR

Bearing load per metre up to 16 tons, shifting the system components after setup even under load

Price on requestplus VAT

-

Base rail ROUND

Bearing load per metre up to 10 tons, shifting the system components after setup even under load, ideal for pallet changeover systems

Price on requestplus VAT

-

Support and base rail DUO

Bearing load per metre up to 20 tons, shifting the system components after setup even under load

Price on requestplus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Leg for spacer block

Connecting elements between spacer block U-form or 3D worktable and support and base rail

Price on requestplus VAT

-

Price on request

plus VAT

-

Holding frame

In combination with pivoting leg or in lengthwise and crosswise direction on the support and foundation track

Price on requestplus VAT

-

Guiding carriage

Superstructures can be shifted even under load, tip-resistance thanks to wrap-around guide

Price on requestplus VAT

-

Guiding wagons

Superstructures can be shifted even under load, extremely smooth-running thanks to ball bearings, roller in hardened version

Price on requestplus VAT

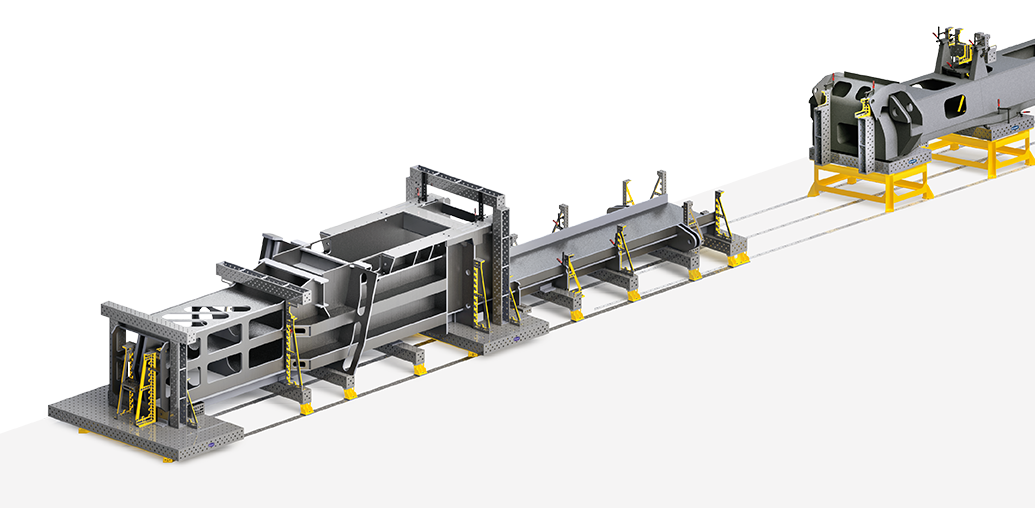

Production of components up to a length of 80 metres and more!

The rail system is installed according to your requirements. Several options are available to you, for example overfloor or underfloor installation. The advantage of underfloor installation is that the entire work area around the rail system is accessible for persons and vehicles. This accessibility makes work easier, reduces the risk of accidents and thereby boosts safety and increases efficiency in your manufacturing process. You have access to the comprehensive selection of DEMMELER accessories to set up your clamping fixtures on the rail system.

Modular

A precise bore grid over long distances from A to Z. Reproduce the system accuracy on your workpieces.

Accuracy

The best accuracy for your large-scale components thanks to an even clamping surface across the entire work area.

Flexible

Combine all system components in conjunction with your rail system.

Quality

The highest quality thanks to optional laser measuring of your rail system.

Planning, installation and acceptance – everything from a single source!

The DEMMELER experts support you from planning your production facilities, right through to manufacturing. We incorporate our expertise from numerous successful projects. You receive support from our expert team, helping you make the right decisions starting in the planning phase. Experienced fitters and technicians will examine the floor characteristics and evenness on request, and offer tips on preparatory measures. Our assembly teams take care of professional installation and the alignment of the base rail system. Training for your production team guarantees proper use of the equipment.

1

Assembly

- Highly accurate templates are used for precise installation.

- We loan you an assembly set with templates free of charge if you choose to install the system yourself.

- Mounting materials (screw set, dowels and shims) are included in the scope of delivery for the support and base rails.

- As a rule of thumb, the installation time is about one hour per running metre.

2

Measuring

- The required accuracy is ensured as early as during installation with laser measuring tools.

3

Acceptance

- Preparation of an acceptance report

- Handover to production

- Annual maintenance and inspections can be offered on request.

Rail types

Support and

base rail

Area of application

Overfloor/underfloor

Standard track width

1000 mm

Support and

base rail XL

Area of application

Overfloor/underfloor

Standard track width

1000 mm

Support and

base rail LINEAR

Area of application

Overfloor/underfloor

Standard track width

1000 mm

Base rail

ROUND

Area of application

Underfloor

Standard track width

1000 mm

Support and

base rail DUO

Area of application

Underfloor

Standard track width

1000 mm

To make things run smoothly

If your workpieces are round or circular, we have the right solution for you with the star-shaped arrangement of our modular rail system. Flexibly adapt the diameters of the clamping devices within the grid system.

Legs you can build on

DEMMELER provides a coordinated range for every task. In addition to an wide choice of tools, a diverse range of sophisticated system accessories is required to produce components on our rail system. Our leg versions tailored to the different rail types and requirements form a secure connection between the rail and 3D clamping system. Exchangeable table legs and sliding legs with castors, for example, enable rapid adaptation to new tasks. Multifunctional guide carriages can be moved to the required position quickly yet precisely.

Leg types

Connecting frame

Set up in length- or crosswise direction.

Very stable design

Leg for spacer block

Set-up heights can be adapted by exchanging legs.

Attachment to system

Sliding leg with castors

Can be moved without using lifting equipment or a crane.

Roller, Tilt safety device

Guide carriage

Can be moved even under load.

Guide cartridge

Can be moved even under load.

For projects that think outside the box

When you have big ambitions, like the company Liebherr, you need machinery to match. With the flexible base rail system, DEMMELER is the ideal partner for the world-renowned crane manufacturer. Thanks to modular extendibility, the base rail system is suitable for producing components with a length of 80 metres and more. The highest accuracy of fit is guaranteed thanks to minimal tolerances.