Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

DEMMELER Ergonomix®M

With the ingenious arrangement of the entire mechanism, the developers at Demmeler were able to create a working space of unrivalled size combined with a small footprint for the Demmeler Ergonomix M manipulator. The manipulator consistently brings the highest payloads into the ideal position. A special characteristic of the Demmeler Ergonomix M product family is the large swivel range of up to 180°. This has the crucial advantage with many work pieces of being able to process them fully in one clamping cycle without turning them over.

Manipulators

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Rotary feedthrough

Rotary feedthrough for querying the state of fixtures, for pneumatic or hydraulic clamping equipment

Price on requestplus VAT

-

Floor plate

With the floor plate, the manipulator can be set onto the floor without needing to be anchored

Price on requestplus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

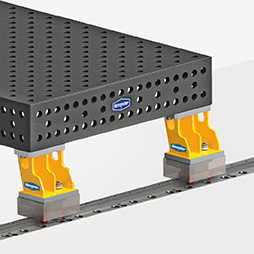

Clamping and adapter plates

With D28 system bores in 100 x 100 mm grid and M24 thread in diagonal grid

Price on requestplus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

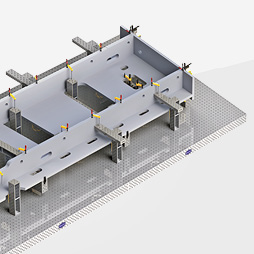

Outstanding flexibility during welding or assembly work

Benefits

- Large work area

- Solid construction

- Low installation height

- Unique swivel range up to 180° as standard

- Comfortable working

- Greater flexibility

- Improved workplace safety

- Increased productivity

DEMMELER Ergonomix M:

Winner of the German federal prize

for innovative performance in the trade

Exact positioning

The movement axes bring your work piece to the desired position at the touch of a button, no matter how often the process step is repeated. To make things even easier, the manipulators can be optionally equipped with the optional teaching controller. You move to the various positions manually and save them. Then the manipulator repeats the programme as many times as you want. You thus improve your productivity and quality.

- At the same time, you eliminate repeated, time-consuming turning and rotating of the work piece, for example using a crane. This greatly reduces non-productive times and leads to significant increases in productivity.

- Higher melting deposition efficiency when welding as most seams can be performed in the optimal position (flat position).

- Simple, fast assembly in the optimum position using standard processes.

Equipment for the Ergonomix®M –

Work without compromise right from the very start

To allow you to enjoy maximum benefit from the many capabilities and advantages of your Ergonomix M, we have a range of accessory equipment for you to use. Thanks to these solutions, you will save valuable time and be able to work more comfortably and with less effort.

1 Operation with pendant control panel

- Potentiometer – enabling reproducible speed settings

- Axis activation at the touch of a button

- Cable length 5 m

2 Controller in the control cabinet

- Master switch

- Compact construction

- Housing integrated in the manipulator

3 Operation with foot pedal

- Foot switch to control the rotation axis of the manipulator by pressing the pedal for left / right rotation

- Foot switch with emergency stop function. Pressing the pedal down all the way stops movement of the rotation axis immediately (panic function)

- The enabling button does not have to be pressed while controlling the rotation axis with the foot switch

4 Teach controller

- Up to 100 programmes with 50 positions each

- Operation via touchscreen

- Start movement by pressing the enabling button

- Offline programming possible

- Editing programmes in a text editor possible

- Data transfer per USB interface

- 10” display

You can move to the positions manually with the buttons and save specific positions in the work piece programme using the teach controller by pressing buttons. This results in a consistent movement sequence from one position to the next. Several different work piece programmes can be stored and called up as needed.

5 Laser scanner

- Personnel and component protection

- Scan radius 3 m (other ranges on request)

- Clearing after area infraction by key-operated switch integrated in the control cabinet door

- Safety zone status display in control cabinet door

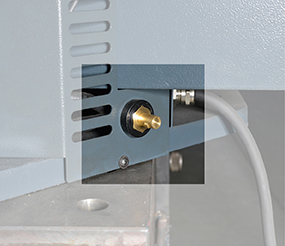

6 Rotary feedthroughs

- Rotary feedthrough for querying the state of fixtures, electrical, 10 signals, teaching controller or controller in premises required

- Rotary feedthrough for pneumatic clamping equipment on worktop, pneumatic, 1-channel

- Rotary feedthrough for hydraulic clamping equipment on worktop, hydraulic, 1-channel

7 Ground connector

Ground connector for feeding the welding ground from the table to the interface next to the control cabinet, including sliding contact and quick coupling. Dinse connection 400 A at 60 % ED, optional 700 A at 60 % ED.