Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

变位机

-

Price on request

plus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

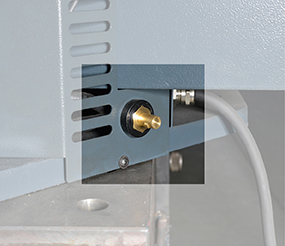

Rotary feedthrough

Rotary feedthrough for querying the state of fixtures, for pneumatic or hydraulic clamping equipment

Price on requestplus VAT

-

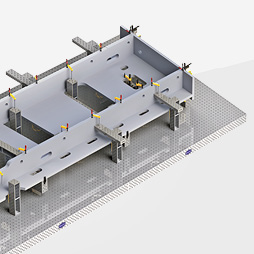

Floor plate

With the floor plate, the manipulator can be set onto the floor without needing to be anchored

Price on requestplus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

-

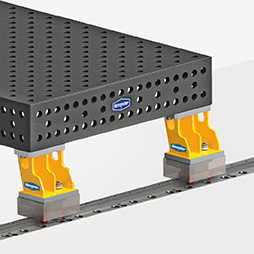

Clamping and adapter plates

With D28 system bores in 100 x 100 mm grid and M24 thread in diagonal grid

Price on requestplus VAT

-

Price on request

plus VAT

-

Price on request

plus VAT

- Foot switch to control the rotation axis of the manipulator by pressing the pedal for left / right rotation

- Foot switch with emergency stop function. Pressing the pedal down all the way stops movement of the rotation axis immediately (panic function)

- The enabling button does not have to be pressed while controlling the rotation axis with the foot switch

You can move to the positions manually with the buttons and save specific positions in the work piece programme using the teach controller by pressing buttons. This results in a consistent movement sequence from one position to the next. Several different work piece programmes can be stored and called up as needed.

- Rotary feedthrough for querying the state of fixtures, electrical, 10 signals, teaching controller or controller in premises required

- Rotary feedthrough for pneumatic clamping equipment on worktop, pneumatic, 1-channel

- Rotary feedthrough for hydraulic clamping equipment on worktop, hydraulic, 1-channel