Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

戴美乐专利机器人刀具更换系统多年以来已经成为市场上最受欢迎的大型机床刀具存储和更换系统。当刀具的数量繁多、重量大,同时使用过程中需要高度灵活性时,我们的刀具更换系统就可以大展伸手了。

该系统最多可容纳750种不同的刀具,并在相应的时间内可调出使用。自动检查刀具属于程序的一部分,并在需要时启动更换。可用电脑进行自由编程,以确保该系统能够广泛的适应各种设备的控制系统。作为带有线性轴和头转换装置的的高端解决方案,该系统可满足您的需要即使是最大的加工中心和最复杂的生产工艺。对于中型设备,我们提供已被验证的系统结构紧凑。

戴美乐刀具架适合您的设备!

- 使用可以旋转超过180°的夹具柱实现了刀具库的高密度性。这也使得夹具柱后的空间可以被充分利用。

- 刀具架形状能完美地适应设备

- 驱动和导轨内置,所以结构相当紧凑

- 刀具间距,槽至槽140mm 更多详细信息,请看页面下端我们的刀具架应用视频。

Application

Fast changing and measuring of tools with weight up to 100 kg and 1.000 mm length

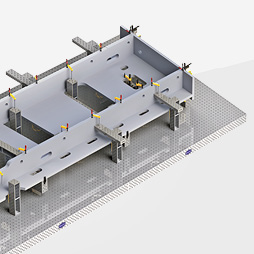

Characteristic Tool Arena

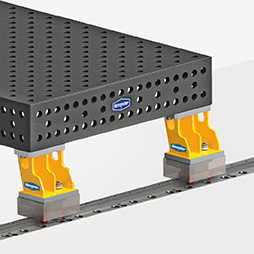

- Small space requirement – distance from segment to mid of linear axis approx. 1.600 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- 2 x 8 setup stations

- Standard gripper

Application

Fast changing and measuring of tools with weight up to 40 kg and 800 mm length

Characteristic Compact Arena

- Small space requirement – radius of segments approx. 1.750 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- Standard gripper

- Can be delivered in one piece

Application

Gripping and handling of tools with weight up to 100 kg and 1.500 mm length

1 Characteristic proportional gripper

- Gripping area of 97,5 to 221 mm

- Integrated measuring system enables an optimum opening stroke of the claws for best tool distances in the rack

- Max. tool diameter of up to 450 mm

- Gripping lock in case of pressure drop is integrated

2 Characteristic cone gripper

- Gripping the tool at the cone; that allows to transfer the tool to a supply unit into the machine via the gripping slot

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

3 Characteristic standard gripper

- Gripping area of 97,5 to 128 mm

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

Characteristic Controller Unit

- Tool management with a very convenient graphical interface

- High machine availability due to an intelligent roboter control with priority management

- Storage and retrieval during machining process

- Automatic space optimized storage system ensures high tool density

- Damaged tool strategy

- Sister tool strategy

- A flexible change moment ensures optimum processing rates

- Identification of tools via RFID chip