Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

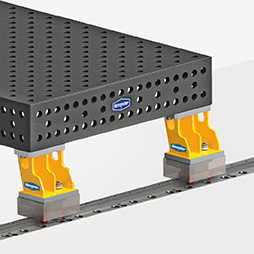

Za leta sodi patentiran sistem za menjavo orodja podjetja Demmeler na osnovi robota k najbolj priljubljenim sistemom za skladišča orodja in menjavo orodij za velike stroje na trgu. Če so potrebne velike zahteve za število in težo orodij pri istočasni visoki prilagodljivosti, potrebujete naše sisteme za izmenjavo orodij.

Sistemi podjetja Demmeler lahko sprejmejo in v rekordnem času pripravijo do 750 različnih orodij. Orodja so pri tem samodejno nadzirana in po potrebi se izvede menjava. S sistemi, ki temeljijo na računalnikih s prostim programiranjem, je zagotovljena zelo visoka zmožnost prilagajanja na različna krmiljenja strojev. Kot najboljše rešitve z linearno osjo in enotami za menjavo glave izpolnjujejo te naprave tudi zahteve največjih obdelovalnih centrov z najbolj kompleksnimi proizvodnimi postopki. Za srednje velike stroje nudimo priznan sistem tudi kot modificirano kompaktno areno.

DemTec® Demmeler Tool Rack se prilagodi vašemu stroju!

- Velika gostota orodij je dosežena z drogom prijemala z vrtenjem za več kot 180°. Na ta način je uporaben tudi prostor za drogom.

- Oblika regala je optimalno prilagojena na razmere stroja

- Zelo kompakten način izdelave z notranje nameščenim pogonom in vodili

- Razmik orodij med posamičnimi mesti 140 mm

- Več informacij najdete na koncu strani v našem posnetku uporabe za Tool Rack.

Application

Fast changing and measuring of tools with weight up to 100 kg and 1.000 mm length

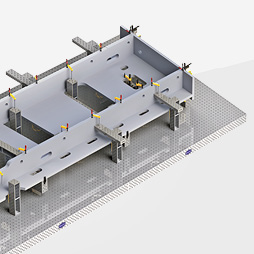

Characteristic Tool Arena

- Small space requirement – distance from segment to mid of linear axis approx. 1.600 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- 2 x 8 setup stations

- Standard gripper

Application

Fast changing and measuring of tools with weight up to 40 kg and 800 mm length

Characteristic Compact Arena

- Small space requirement – radius of segments approx. 1.750 mm

- Possibility to integrate different types of robots – depending on type of application and load

- Possibility of handling all usual types of toolholders: HSK A 63, HSK A 100, SK 40, SK 50, Capto C6, Capto C8

- Standard gripper

- Can be delivered in one piece

Application

Gripping and handling of tools with weight up to 100 kg and 1.500 mm length

1 Characteristic proportional gripper

- Gripping area of 97,5 to 221 mm

- Integrated measuring system enables an optimum opening stroke of the claws for best tool distances in the rack

- Max. tool diameter of up to 450 mm

- Gripping lock in case of pressure drop is integrated

2 Characteristic cone gripper

- Gripping the tool at the cone; that allows to transfer the tool to a supply unit into the machine via the gripping slot

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

3 Characteristic standard gripper

- Gripping area of 97,5 to 128 mm

- Max. tool diameter of up to 400 mm

- Gripping lock in case of pressure drop is integrated

Characteristic Controller Unit

- Tool management with a very convenient graphical interface

- High machine availability due to an intelligent roboter control with priority management

- Storage and retrieval during machining process

- Automatic space optimized storage system ensures high tool density

- Damaged tool strategy

- Sister tool strategy

- A flexible change moment ensures optimum processing rates

- Identification of tools via RFID chip