Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

We are developers, manufacturers and users –

the triple competence for quality, usability and efficiency

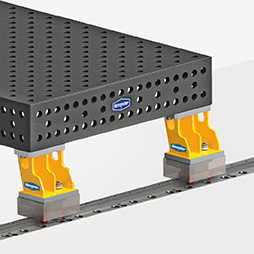

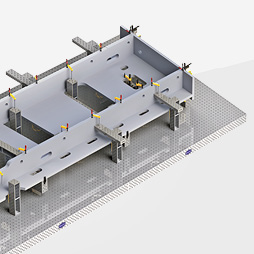

For 60 years, DEMMELER has been developing innovative solutions for machine and plant construction in numerous branches of industry and the craft. We develop and produce pioneering premium products for the automation of machine tools and welding and clamping technology. In addition to our invention of the 3D welding table systems, today's industrial standard in fixture construction, we want to influence the production in Industry 4.0 with our new technologies in the future.

We place great emphasis on the highest quality at a fair market price in the production of our products. We are firmly convinced that investing in a durable, competitive DEMMELER product is far more profitable than the initial savings when buying a cheap imitation. Our strategy is confirmed by the fact that as a strong partner we are able to count many small and medium-sized trades companies as well as renowned international groups among our customer base.

The company's growth was accompanied by several product developments, which were first produced only for their own production facilities. Put through their paces, we now deliver these products to customers worldwide. In addition to the 3D clamping system, these also include the turning, tilting and carousel rotary tables, as well as 3-axis manipulators, tool arenas and tool machine components.

Development and design

At the DEMMELER development and design centre in Heimertingen, our specialists are continuously developing and working on new product developments that make work as efficient and smart as possible. We also focus on an extremely long durability of our products.

Made by professionals for professionals

As the inventor of the 3D clamping system, we are not only a manufacturer, but also use our products for our own production. Our most critical customer is therefore us.

Production at DEMMELER in Heimertingen "Made in Germany"

Our top trained specialists and highly automated production and guarantee a consistently high product quality.

The highest "made in Germany" quality

"Made in Germany" is now regarded as a seal of quality and a sign of quality. We develop and produce exclusively in Germany in order to continuously check and optimise our production processes, i.e. in order to ensure the high quality of our products.

Thanks to our steadily growing and highly specialised team, we ensure that our products will continue to meet the needs of our customers all over the world. The commitment of our employees has already resulted in a number of ground-breaking industry innovations.

Sustainability and future viability

We are aware of the special responsibility for future generations, especially as a family-owned and operated business. We protect our ecological environment by deliberately making our production processes as sustainable as possible. Because people are increasingly living off of fewer resources.

DEMMELER relies on careful raw material selection as well as technical innovations. For example, the company is supplied with its own solar power thanks to its sophisticated energy supply.

Precision redefined

We set high standards for our production, since it forms the basis for our excellent quality products. We only use materials from certified suppliers, which is a crucial requirement to consistently guarantee a consistently high production quality.

Ultimate precision is a key quality characteristic of our products. That is why we place the utmost value on the dimensional accuracy of all parts that leave our plant. We rely on the latest generation of measuring tools and test systems: 3D coordinate measuring machines, laser measuring systems and optical test equipment.

Working at DEMMELER

Due to our great growth, we are always looking for talents and highly motivated, committed and creative team players who can shape the future with us. Your prospects as an employee at DEMMELER are as broad as our product range.

Find out more about DEMMELER as an employer, our current vacancies or an apprenticeship or internship at DEMMELER.