Fenster schließen

Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Robotix turning unit:

Easily position heavy loads up to 14,000 kg

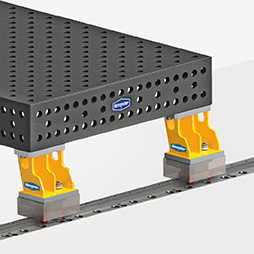

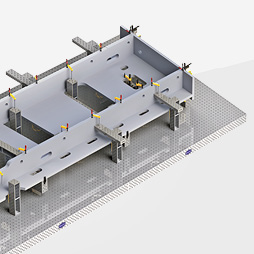

The Robotix turning unit from DEMMELER can be used to move long and heavy workpieces into the ideal position for welding and assembly work so that they can be lifted and lowered or turned in both directions using two electric lifting columns. Both of the turning unit's columns are mounted on the floor of the production facility. There is the option to mount the turning unit on the DEMMELER rail system. This allows the distance between the two face plates to be set to different workpiece sizes.

Benefits

- Ergonomic work that protects your back

- Improved workplace safety

- Ultimate productivity and improvement in quality thanks to the staff being in the ideal position for working

- Higher melting deposition rate when welding, as most seams can be produced in the optimal position (flat position)

- No need for time-consuming reclamping – the workpiece is lifted and turned in a single clamping cycle

Basic model of the Robotix turning unit

| Description | WE 2000 | WE 4000 | WE 6000 | WE 8000 | WE 10000 | WE 12000 | WE 14000 |

|---|---|---|---|---|---|---|---|

| Load capacity per column [kg] | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 |

| Total load capacity [kg] | 2000 | 4000 | 6000 | 8000 | 10000 | 12000 | 14000 |

| Standard height of rotation axis [mm] | 540 | 600 | 600 | 600 | 600 | 600 | 600 |

| Effective stroke [mm] | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

| Turning radius [mm] | 2240 | 2300 | 2300 | 2250 | 2250 | 2250 | 2250 |

| Torque [Nm] | 2000 | 3000 | 6000 | 10000 | 10000 | 12000 | 12500 |

| Controller at control cabinet | yes | yes | yes | yes | yes | yes | yes |

Equipment that is perfectly tailored to your specific tasks

Controller at control cabinet

- Axis activation at the touch of a button

- Optional potentiometer, for setting the speed

Safety laser scanner

- Ensure both maximum safety and productivity

- Individually adaptable protection zone

- Display unit with monitor view/camera view and a clearly visible status LED for ultimate ease of use

Adapter plates

- Adapter plates with D28 system bores in a 100 x 100 mm grid and M24 thread are available as an option

Optional equipment versions (available on request)

- Adapter plates from dia. 600 to dia. 1500 mm

- Slave lifting block is mobile and not stationary

- Drive lifting block is mobile and not stationary

- Welding current supply 350 A

- LCD display on the control box

- Variable frequency control of the rotary drive for continuously variable speed selection up to 12,500 Nm

- Variable frequency control of the rotary drive for continuously variable speed selection above 20,000 Nm

- Adjustable torque limit using friction clutch in the rotary drive

- Area scanner for preventing the system from colliding with an obstacle or turning onto an obstacle

- Effective stroke increased every 100 mm

- Special flange plate or drilling pattern change