Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Flexible and versatile welding automation solutions with the new COBOT WeldSpace 4.0® HOUSE 40/20

With the further development of COBOT WeldSpace 4.0® TABLE 24/12, HOUSE 40/20 from DEMMELER, even small and medium-sized companies can get to grips with automated and professional welding production in next to no time thanks to the fast commissioning. Whether individual parts, parts from series production, or small batch sizes with a large variety of parts – you save time in welding and reworking.

Maximum flexibility in the equipment

Version

COBOT WeldSpace 4.0® House 40/20

Either with Cobots or industrial robots from FANUC

Designed for operation with easy-to-program cobots or ultra-productive industrial robots

Large workspace

4000 x 2000 x 2000 mm for ultimate flexibility

Optionally partition wall

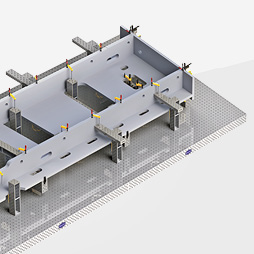

Two separate workspaces with dimensions of 2000 x 2000 x 2000 mm each thanks to removable partition wall and four roller shutter doors

Highly productive welding

with up to two robots simultaneously

Seventh axis

to make the welding robot reach extra large

Optional two-axis manipulator

with load capacity of 500 kg

Optionally with base rail system

configured for shuttle operation

Operating the cell with industrial robots

When operating the cell with industrial robots, a multitude of manipulators and turning units are available with or without counter-support

Individually configurable workspaces

3D welding table 4000 x 2000 x 2000 mm

- Large workspace

- Roller shutter doors close automatically during the welding process

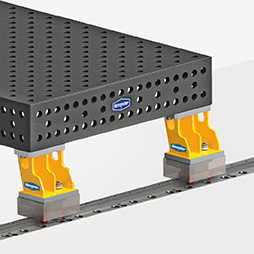

- Can be optionally configured with the DEMMELER base rail system

Two 3D welding tables each with dimensions of 2000 × 2000 mm

- Two workspaces split by a movable partition wall

- Shuttle operation between SPACE A1 and A2

- Roller shutter doors close automatically and separately during the welding process

- Both workspaces can be optionally configured with the DEMMELER base rail system

Two-axis manipulator + 3D welding table 2000 × 2000 mm

- Welding areas are split by the partition wall

- Shuttle operation between SPACE A1 and A2

- Roller shutter doors close automatically and separately during the welding process

- Both workspaces can be optionally configured with the DEMMELER base rail system

3D welding table on DEMMELER rail system

- Can be optionally configured with the DEMMELER base rail system for shuttle operation

- Roller shutter doors close automatically during the welding process

Equipment that is perfectly tailored to your specific tasks

Perfectly coordinated welding processes

- Welding systems designed for the COBOT WeldSpace 4.0®

- Robot welding equipment from the Fronius brand

- Extensive job libraries

- Integration and software extension of the DEMMELER WeldSpace 4.0® software

- Input of the welding jobs from the power source and simple selection using a list on the control panel

High-quality welding robots

- FANUC CRX Cobot: User-friendly collaborative robot for users with little or no robotics experience.

Intuitive programming and operating concept

- Professional welding software with numerous features for industrial welding, such as arc sensor, tactile sensor, etc.

- Programming and teaching of points using the Teach Pendant user interface for pass-through teaching and easy drag-and-drop programming

Ultimate flexibility and efficiency

- The cell can be flexibly integrated and adapted to changing requirements

- You have access to the comprehensive selection of DEMMELER accessories to set up your clamping fixtures as well

Maximum safety

COBOT WeldSpace 4.0® contains all safety-relevant equipment:

- Protective enclosure with protective welding glass and roller shutter doors made from aluminium cladding with viewing elements

- Depending on the model, protective devices such as safety light grids and curtains, as well as protective welding walls

Torch cleaning station

- Optimum and reliable cleaning of the gas nozzle ensures a reliable welding process and increases system availability

Download Product Brochure

COBOT WeldSpace 4.0® HOUSE 40/20

For more information about the DEMMELER COBOT WeldSpace 4.0® HOUSE 40/20 and its equipment options, simply download the product brochure.

Contact

Get in touch!

Would you like individual advice on our products and services? Contact us and together we will find a solution.

We look forward hearing from you!