Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Original 3D welding tables and automation solutions – perfectly tailored to your requirements

Nowadays, solutions need to perfectly fulfil various tasks. Ideally as a complete solution, a modular, coordinated system. This is why we continuously optimise our products to meet the needs of all relevant industries. This results in innovative and efficient solutions which perfectly fulfil their intended purpose. Robust and reliable. Efficient and economical. Modular and versatile. That's the 3D clamping system from DEMMELER.

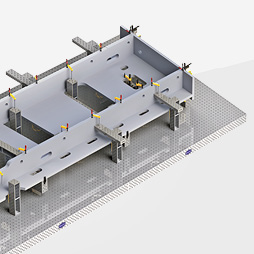

COBOT WeldSpace 4.0®

In the future, advances in digitalisation and automation will also change the processes in welding production. Particularly in the manual welding of classic sheet metal components, the new technology – welding with collaborative robots – can eliminate the need for valuable skilled workers to perform tiring routine and repetitive tasks. With the COBOT WeldSpace 4.0® from DEMMELER, even small and medium-sized companies can get to grips with automated and professional welding production in next to no time thanks to the fast commissioning and extremely simple programming. Whether individual parts, parts from series production, or small batch sizes with a large variety of parts, you save time in welding and reworking.

Modular clamping system

Already by 1990, DEMMELER set the standards on the market as the inventor of the 3D clamping system: Originally intended for the company's own production, the device system proved to be a quantum leap in metal processing and today is an international industrial standard due to the many possible applications and combinations. The modular clamping system makes them highly flexible, and they can be found in both small specialist companies and major industrial groups.

Flexible positioning

Welding and assembly in an optimal position. A good ergonomic workplace design allows more efficient and error-free workmanship, protecting staff against health hazards even during laborious tasks. The manipulators from DEMMELER offer preventive occupational safety and ensure a more efficient and safer working environment which, as a result, leads to improved quality in production. Whichever way you look at it, DEMMELER manipulators are indispensable.

Flexible tool handling

DEMMELER's automation systems are used wherever extremely efficient and high quality products are manufactured. Our robot-assisted tool change systems can accommodate up to 750 different tools and make them available in record time. We place great importance on individual support and comprehensive service. We guarantee top quality and extreme precision. All area are oriented to and contribute to this purpose.

Exact positioning and flexible processing

No matter whether positioning, interpolation or rapid turning – we have the right solution for your complex applications. Our rotary, tilt and carousel rotary tables set a clear mark due to the extremely robust design as well as a high level of precision in the micrometre range, speed and repeatability. Whether a hydrostatic linear or rotary axis, roller bearing axles or also a combination with both – we create the right solution based on our experience from more than 750 projects.

Highest precision

Dimensions up to 20 m in length, piece weight up to 100 tonnes and tolerances in the micrometre range – all of these are parameters that have accompanied us for years and characterise us as a supplier of well-known machine tool manufacturers. The main focus of work here is on the production of basic components, such as X, Y and Z axes, machine beds, machine frames, portals and clamping floor plates, which are used in our customers' ultra-modern CNC machines.

Customer stories

Do you want to know how our products are used in practice?

Companies all over the world rely on DEMMELER to boost their productivity and improve safety and ergonomics at the workplace. Here you can find a current selection of successful projects with companies from various different industries and a description of the impact DEMMELER has had on their everyday work.

current topics

News & Stories

DEMMELER supports fundraising campaign for Ukraine with 15,000 €

Viktoria and Christian Brugger, managing directors of B&S Stromkonzepte, have launched a fundraising campaign together with the local AWO group in Altenstadt.

Christmas trip by the art blacksmiths Hoppen

On the 14th December 2023 we welcomed the art blacksmith Hoppen from Dattenberg. Specializing in restoration and blacksmithing, their projects includes the restoration of the historical lattice work from 1723 for the Holy Stiege pilgrimage church in Bonn.

St. Nicholas was here

We would like to say thank you to all of our colleagues at DEMMELER for their great commitment throughout the year and wish you a reflective pre-christmas period ⭐!

Trade fairs

Demmeler as employer

“Interesting tasks and top colleagues!”

DEMMELER has been creating innovative solutions for machinery and plant construction for over 60 years now. These set global standards. Our technological advantage based on intensive development work is the reason for many customers' collaboration, often spanning decades. This wide-ranging industry orientation offers exciting projects and varied tasks. Become part of our high-performance team.

DEMMELER in numbers

60+

More than 60 years

on the road to success

20.000 m²+

Production and

logistics area

200+

Employees

One system for various tasks

The 3D clamping system from DEMMELER.

THE original from the inventor.

The standard solution for industry and trade

Automation

Machinery

Steel / metal constructions

Vehicle construction

Shipbuilding

Aircraft construction

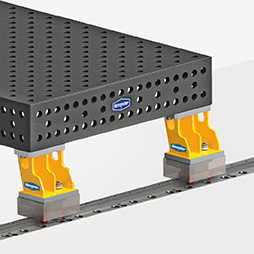

If you are looking for a high quality and stable welding table, DEMMELER, as the inventor of the welding table, is the right partner. Our welding table and clamping system has already received several awards and is part of the international industrial standard. A modular welding table from DEMMELER is very versatile. It opens up a wide range of possible uses. Thanks to its innovative design, a clamping device can be set up for almost any workpiece in record time. Using the grid system as a grid square, workpieces can be clamped with positioning and clamping bolts on all 5 sides over the entire 3D welding table. Target dimensions can be set and fixed quickly as well as precisely for each workpiece. During the tacking and welding process, the individual welding parts are clamped to the corresponding surfaces or points. For an optimal position.

In order to cope with both small and extreme loads, DEMMELER has brought various welding tables onto the market. All welding tables belong to one line: PROFIPremiumLINE, PROFIPlusLINE, PROFIEcoLINE or HobbyLINE. The particular advantage of our welding tables lies in their modular structure. For example, if you start with a welding table from the PROFIEcoLINE, you can gradually add other components that you can order directly from us. In addition, you have the option of connecting several 3D welding tables directly or with spacer blocks. This gives you a work surface that adapts entirely to your individual needs. One and the same welding table can therefore be used to manufacture very different components and products. This includes, for example, machine housings, frames, pipelines, banisters, filling systems, vehicles, gates, control cabinets, cabins and much more. A wide variety of configurations can be implemented depending on your requirements.

We are here for you

Our service –

Fast, competent and reliable

We offer a wide range of support services in addition to our technical and innovative solutions. Take advantage of our comprehensive services, from the service hotline to spare parts deliveries to direct on-site assembly. Short response times are a matter of course.

DEMMELER

Servicehotline

COBOT WeldSpace 4.0®

Phone: +49 83 35 98 59-961

Mail: service-cobot(at)demmeler.com

3D Welding tables

Phone: +49 83 35 98 59-962

Mail: service-welding-table(at)demmeler.com

Manipulators

Phone: +49 83 35 98 59-963

Mail: service-manipulator(at)demmeler.com

Rotary tables

Phone: +49 83 35 9859-964

Mail: service-rotary-table(at)demmeler.com

Tool arenas

Phone: +49 83 35 9859-965

Mail: service-toolchanger(at)demmeler.com