Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Where design meets expertise – MetallArt Treppen produces sophisticated and unique staircases

MetallArt Treppen GmbH, based in the town of Salach in south-western Germany, produces customised staircases for sophisticated architecture. The company, which employs 100 people, developed from a simple blacksmith's shop into a highly-specialised company for custom-made designer staircases with an impressive portfolio. Their many eye-catching projects can be found in elegant hotels, contemporary business premises and private buildings. With its sophisticated collection of staircases and railings made from steel, glass and wood, MetallArt was awarded the German metalwork prize (Deutscher Metallbaupreis) in 2022 in the staircases and railings category.

MetallArt Treppen GmbH uses the ultra-productive and versatile 3D clamping system from DEMMELER for its welding production processes to make pieces with unique designs.

Customised staircases for sophisticated architecture

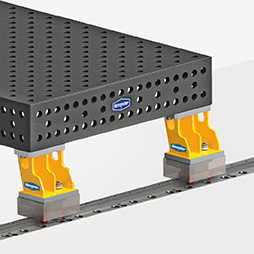

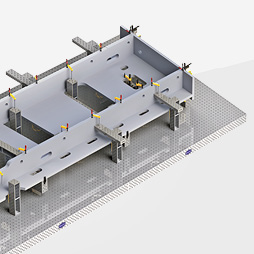

Both the expectations of demanding customers and the company's own quality requirements for its exclusive staircase designs are high. The company therefore uses state-of-the-art technical equipment in the form of the 3D clamping system from DEMMELER. A 3D welding table, measuring 3000 x 1500 mm, with a scissor list is primarily used to produce pre-assembled components from which the exclusive MetallArt staircases are made. Flat metal sheets are stapled and firmly welded with braces and stiffeners to form pre-assembled components. In addition, the scissor lift can then be used to quickly and infinitely adjust the height of the welding and assembly station. This creates an ergonomically optimised working environment. The railings and handrails are produced on another DEMMELER 3D welding table measuring 1500 x 1000 mm. Once they have been bent and rounded, the stainless steel and steel pipes are constructed, measured and welded with the assistance of clamping accessories. "The clamping system from DEMMELER helps us immensely. The beauty of the system is its versatility, quick deployment, levelness and, above all, precision," says Steffen Bayer, Overall Production Manager and Authorised Officer at MetallArt. The greater the degree of precision when securing, stapling and welding the pre-assembled components, the easier it will be to construct the entire staircase – and to do so with greater precision.

In contemporary architecture, spiral staircases have become a creative element of design. In addition to its functionality, staircases need to have a strong, stand-out design.

Highly productive and flexible solutions for welding production

MetallArt is now ideally equipped for precisely securing and clamping components. The multifunctional tool from DEMMELER can be used in any number of combinations. "The 3D welding table system enabled us to considerably increase our quality and efficiency. All of the accessories bring such an array of benefits that we no longer need to build any structures. The screw clamps, stops and brackets are within easy reach of the workstation.

You just need to position the component and everything is already quickly and precisely secured thanks to the grid system. We're very satisfied with our 3D welding table from DEMMELER. Of course, there are other alternatives but when you've got a DEMMELER welding table, you don't have any more problems," says Steffen Bayer.

Flat metal sheets are stapled and firmly welded with braces and stiffeners to form pre-assembled components. The scissor lift can be used to quickly and infinitely adjust the height of the welding and assembly station.

MetallArt Treppen GmbH

Hauffstraße 40

73084 Salach · GERMANY