Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Schulz Fördersysteme GmbH –

Welding at the highest level with ultimate flexibility

Schulz Fördersysteme GmbH specialises in metalworking. In addition to sheet metal parts, edge parts and welded assemblies, the company also produces conveyor systems. Around 100 members of staff work for the brands Schulz Fördersysteme and Blechbearbeitung Thüringen at the Geratal site in Thüringen. As a certified specialist business in accordance with DIN EN 15085-2 CL1, Schulz Fördersysteme has a special responsibility for producing highly safety-relevant components for rail vehicles. The fact that the company sees itself as a system supplier with a high vertical range of manufacture is also evident from its state-of-the-art production processes.

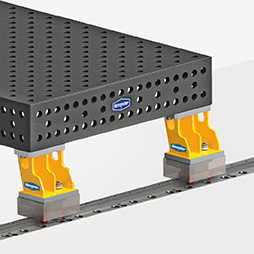

The complete package for a quick and professional introduction to automated welding

A few months ago, the company also started to use a COBOT WeldSpace 4.0 from DEMMELER alongside a DEMMELER manipulator and rail system. With the new COBOT system, Schulz Fördersysteme can quickly and easily adapt to varying component geometries or sizes in production. In addition to being easy to program, the COBOT WeldSpace 4.0 is designed to reduce the physical exertion of welders. Welders are often forced to work in uncomfortable positions as the weld seams are frequently hard to reach. This is why the SPACE B workspace of the COBOT system was equipped with a two-axis manipulator: Workpieces up to 500 kg can be easily clamped in the ideal flat position. There is no longer a need for time-consuming reclamping of workpieces and, thanks to the manipulator's rotary axis, even circumferential seams can be welded without any problems.

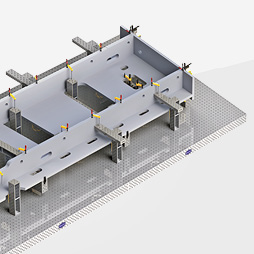

Productivity³: Shuttle operation parallel to main time

Multiple parts, including different ones, can be welded simultaneously using the COBOT WeldSpace 4.0. The automatic enclosure movement makes it possible to work in multi-station mode. While the robot is welding on one side, the operator – protected by retractable roller doors with aluminium cladding and integrated welding protection glass – can set up and reclamp on the other side in parallel (two-station operation).

"We are a contract manufacturer specialising in sheet metal machining for a range of different industries: Automotive, rail, machinery and plant construction, conveyor technology, furniture and metal construction. Our flexibility has always been one of our greatest strengths compared to our competitors," states Carsten Stein, Managing Director at Schulz Fördersysteme. DEMMELER assists us with its large variety of products, which can be used to produce small and medium batch sizes. We appreciate the excellent quality of DEMMELER products – and the outstanding service!"

SCHULZ FÖRDERSYSTEME GMBH

An der Glashütte 10

99330 Geratal – OT Gräfenroda · GERMANY