Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

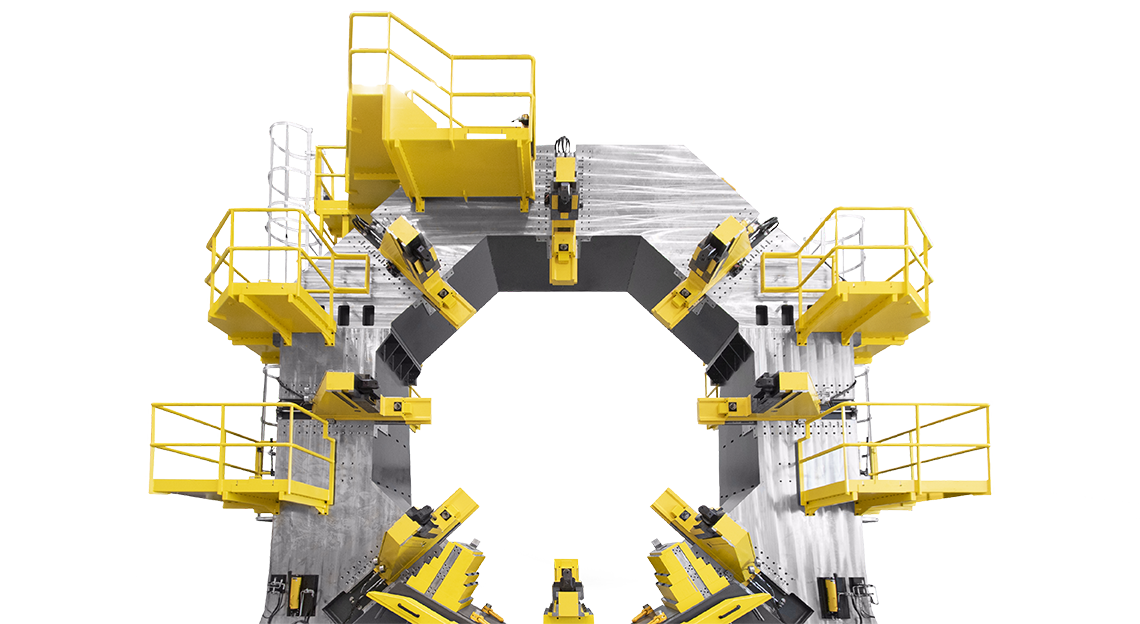

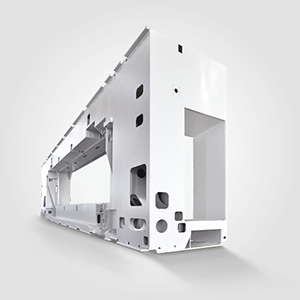

With our well-equipped machinery, the use of the latest tool technologies and a high level of automation, we are able to process and produce parts of the highest quality very economically. We manufacture everything from small parts to complex workpieces such as machine beds, stands, gearbox housings, etc. with dimensions of up to 26 m in length, both in small quantities and in large batches. You will receive your completely ready-to-assemble modules from us. We are also able to provide you with the entire engineering process, from development to construction and project planning.

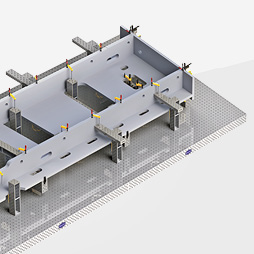

In our assembly department we are able to complete entire systems and special machines. Programs for a wide variety of workpieces are created graphically and interactively on our programming system.

The common CAD formats (e.g. Iges, STEP, DXF, etc.) are often read into the system, thus drastically reducing the programming time. Based on the experience and know-how of our employees, you get the best possible benefit.

From design to assembly –

our know-how for you

DEMMELER is not only known for its comprehensive manufacturing expertise, our customers value us also as an experienced contact and development partner with broad know-how in the business areas of construction, welding, turning, milling, painting and assembly.

Our own development team accompanies every project from specification to production and ensures that finally a technically and economically convincing result is achieved. Founded in 1961 by Ludwig Demmeler, our owner-managed company has developed solidly through constant growth and today works for international, well-known companies from a wide range of industries.

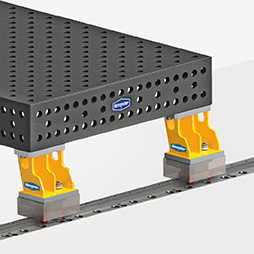

Our service portfolio in contract manufacturing

As part of our contract manufacturing, we weld and process components up to a length of 26 m with 100 t up to components weighing just a few grams. In order to achieve optimal product quality, we have a very high level of vertical integration in-house and therefore have all the quality-critical parameters under our own control. On an area of over 20,000 square meters, we have a very large machine park including the most modern measuring and testing technology for quality control.

We place high demands on our production because it is the basis for our excellent quality products. The best is just good enough. We only use materials from certified suppliers, an essential prerequisite for consistent manufacturing quality. Highest precision is one of the most important quality features of our products. That's why we attach great importance to the dimensional accuracy of all parts that leave our factory. We rely on the latest generation of measuring tools and testing systems: 3D coordinate measuring machines, laser measuring systems and optical testing devices.

In addition, DEMMELER meets comprehensive welding quality requirements in both series and individual production in accordance with ISO certification DIN EN ISO 3834-2:2006. Large-format components up to 26 m long can be manufactured extremely efficiently and with high precision using robot systems. All of this is the framework for excellence. Ultimately, however, the commitment of each individual employee determines economically crucial factors such as quality and reliability. We owe our high standards to the experience and daily commitment of our expert employees in all areas of our production.