Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Gamechanger for COBOT welding: Highly efficient welding of components with a length of up to 12 metres

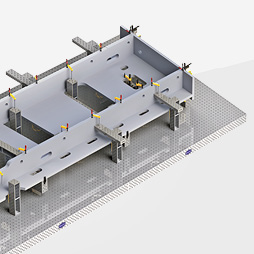

Clamping and welding components up to a length of twelve metres. What was previously only possible with industrial robot solutions, the new COBOT WeldSpace 4.0® LINEAR from DEMMELER does with reliable repeat accuracy and lasting precision. The result is precise weld seams and greater welding productivity. The fully equipped welding cells with welding robot and welding technology offer scope for unique modularity and flexibility with a wide range of possible configuration options.

| Technical specifications | LINEAR 40/15 F | LINEAR 80/15 F |

| External dimensions of cell | 4900 x 2200 x 1975 mm | 8900 x 2200 x 2700 mm |

| Dimensions workspace | 4500 x 1200 mm | 8500 x 1200 mm |

| Weight | approx. 4110 kg | approx. 5350 kg |

| Max. last | 10000 kg | 10000 kg |

| Linear axis travel Fanuc CRX welding robot | 3000 mm | 7000 mm |

Closed Welding protection wall and partition wall that divides the workspace into SPACE A1 and A2

Product highlights

The Fanuc CRX collaborative welding robot travels on a dynamic linear axis (mathematically coupled for synchronised movements with the robot – 7th axis).

In addition to the robot, the welding power source, the wire supply, the welding fume extraction system and the torch cleaning station also move.

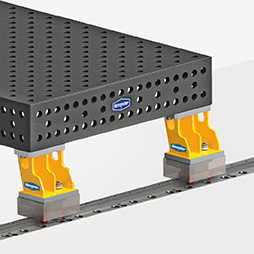

Integrated Demmeler® 3D welding table D28 in the size 8400 x 1395 mm (due to the modular design, also available in other lengths of 3 m, 6 m, 9 m and 12 m on request). The entire range of Demmeler® 3D clamping systems is available for precise clamping of the workpieces.

Demmeler® single-axis manipulator with counter bearing

The manipulator's rotary axis is fully integrated into the robot controller. The manipulator and robot axes move simultaneously, which ensures greater efficiency and speed during welding.

For components up to 3 m or 7 m with a maximum weight of 2000 kg

Maximum productivity

Full accessibility: The welding protection wall can be completely folded away at the front. The system is open at the top and can be loaded by crane or forklift truck.

Dividing the workspace into SPACE A1 and A2 using a partition wall creates an additional workstation and enables highly efficient working in two-station operation.

The integrated single-axis manipulator with counter bearing positions workpieces weighing up to 2,000 kg in the optimum welding position, eliminating the need for time-consuming reclamping of workpieces.

DEMMELER® WeldSoft F 1.0

Simple programming via drag-and-drop

Whether you are an experienced programmer or a beginner – the professional welding software DEMMELER® WeldSoft F 1.0 offers numerous features for industrial welding, such as arc sensor, tactile sensor, etc. Programming and teaching of points using the Teach Pendant user interface for pass-through teaching and easy drag-and-drop programming.

Programming with the Tablet Teach Pendant

Clear programme management with display of various parameters

- Current runtime component

- Job runtime

- Arc time

DEMMELER® job library

All COBOT and welding parameters in one place

Extensive protected DEMMELER® job library – High-performance welding jobs developed in DEMMELER‘s welding laboratory

Registered users can use the job library of the DEMMELER® WeldSoft F 1.0 software to access over 100 protected welding jobs with all the important parameters matched to the material, power source and welding process. You can also view the videos on the welding processes via QR codes on the stored data sheets.

Type of welding seam depending on material

Fillet weld

Corner weld

Overlap weld

Vertical weld

Equipment that is perfectly tailored to your specific tasks

Perfectly coordinated welding processes

- Welding systems designed for the COBOT WeldSpace 4.0®

- Robot welding equipment from the Fronius brand

- Extensive job libraries

- Integration and software extension of the DEMMELER WeldSpace 4.0® software

- Input of the welding jobs from the power source and simple selection using a list on the control panel

High-quality welding robots

- FANUC CRX Cobot:

User-friendly collaborative robot for users with little or no robotics experience.

Intuitive programming and operating concept

- Professional welding software with numerous features for industrial welding, such as arc sensor, tactile sensor, etc.

- Programming and teaching of points using the Teach Pendant user interface for pass-through teaching and easy drag-and-drop programming

Ultimate flexibility and efficiency

- The cell can be flexibly integrated and adapted to changing requirements

- You have access to the comprehensive selection of DEMMELER accessories to set up your clamping fixtures as well

Maximum safety

COBOT WeldSpace 4.0® contains all safety-relevant equipment:

- Welding safety curtains for sliding and folding open

- Secured workspaces and laser scanners

High-vacuum extraction system

Travelling high-vacuum extraction system in combination with powerful extraction welding torch

- Separates more than 99.9% of the captured welding fume particles

Download Product Brochure

COBOT WeldSpace 4.0® LINEAR

For more information about the DEMMELER COBOT WeldSpace 4.0® LINEAR and its equipment options, simply download the product brochure.

Contact

Get in touch!

Would you like individual advice on our products and services? Contact us and together we will find a solution.

We look forward hearing from you!