Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

Automated welding from small batches to series

Collaborative welding robots help counteract the shortage of skilled workers and are suitable for small and medium-sized companies as well as large companies. The COBOT WeldSpace 4.0 TABLE 24/12 from DEMMELER ensures high welding quality with large flexibility, intuitive operation and intelligent features - even with tolerances and thermal distortion. Especially when welding classic sheet metal components manually, the new technology, welding with collaborating welding robots, can relieve valuable specialists from tiring routine and repetitive tasks. Robot technology also makes the job of welding much more attractive. Especially young people are becoming more enthusiastic about welding work again.

The COBOT WeldSpace 4.0® TABLE 24/12 welding cell comes with everything you need

The simple programming and high flexibility of the collaborative welding solution COBOT WeldSpace 4.0 make it possible to weld workpieces automatically in the shortest possible time. In this way, not only series but also small quantities can be produced economically. Thanks to its high cost-effectiveness, quick commissioning and compact design, cobot welding is perfect for small and medium-sized companies as well as large companies.

Basic equipment

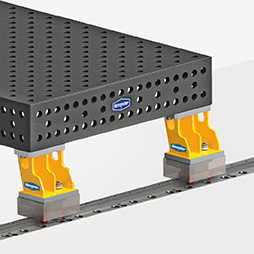

DEMMELER 3D welding table

In the system size D28 from DEMMELER

LED strips

On all side corners signify processes and machine statuses

Smart Toolbox

With three lockable drawers, clamping tools are stored within easy reach

DEMMELER WeldSpace 4.0® Software

The best settings tailored to the power source, welding process and torch with simple and fast operation

Either with a Cobot from Universal Robots UR or FANUC

Collaborative robot UR10e from Universal Robots or FANUC Cobot CRX-10iA

Connection options for a central production facility exhaust system

On the left or right side and two at the top of the system

Special equipment

Extension set SPACE A into SPACE A1 / A2

With this extension set, the SPACE A workspace can optionally be divided into two workspaces – SPACE A1 and SPACE A2.

Two-axis manipulator

Modular two-axis manipulator up to 500 kg payload for professional workpiece handling and circumferential seam welding with the rotary axis

Integrated and professional high-performance welding system

FRONIUS Robot welding equipment

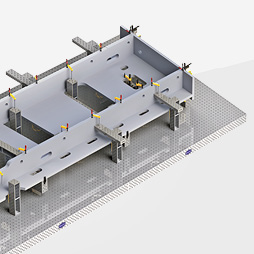

Multiple workspaces

Automated welding in shuttle operation

- The automatic enclosure movement makes it possible to work in multi-station mode

- While the robot is welding on one side, the operator – protected by retractable roller doors with aluminium cladding and integrated welding protection glass – can set up and reclamp on the other side in parallel (two-station operation)

- With this extension set, the SPACE A workspace can optionally be divided in the centre into two workspaces – SPACE A1 and SPACE A2. This makes it possible to operate the welding cell in three-station mode

Intuitive programming and operating concept

WeldSpace 4.0® Software guides you step by step to the perfect welding result

The heart of the COBOT WeldSpace 4.0® is its ease of use. Developed by our welding experts the software is perfectly adapted to the robot and welding process. The new way to programming: by activating the Free-Drive function,

the COBOT can be moved by hand to the place where welding is to be started and stopped. Waypoints and welds can be programmed by simply pressing a button. This allows you to create professional welding programs simply at the touch of a button. The welder has full access to all relevant functions of the welding system with only one control panel and can select, set and save parameters in the robot control.

Software operation

All COBOT and welding parameters in one place

The intuitive user interface of the WeldSpace 4.0® Software for operating the COBOTS makes it easy to get started. Even employees without programming knowledge can easily learn to control the robot. All parameters relevant to welding must be selected, set and saved in the robot control.

The best settings for the power source, welding process and torch are always available. On the user interface of the WeldSpace 4.0® Software, the operator has the option to access welding characteristics and parameters in the job library.

Optionally with Cobot from Universal Robots UR or FANUC

The UR version is particularly suitable for operators without programming knowledge

- With the WeldSpace software from DEMMELER, the welder has full access to all relevant functions of the welding system with only one control panel. All parameters relevant to welding must be selected, set and saved in the robot control.

- The 360° axes make the overhead-mounted robot very flexible and easy to use. The robot arm is extremely easy to control and makes calibrating as simple as it gets..

- The amount of training required is very low. Experience has shown that welders can learn to create welding seams after just one day of training.

The F Version uses the familiar drag-and-drop technology from FANUC

- With the professional welding software DEMMELER WeldSoft F 1.0, the system offers numerous features for industrial welding, such as the arc sensor to compensate for bending and part tolerances during arc welding, the automatic TCP compensation by moving to the reference tip and the tactile sensor to detect position shifts in the workpiece to compensate.

- The 3D overview simulates the robot and manipulator movements of the program without the robot actually having to complete the movements. Thanks to offline programming, the teach pendant can be simulated on the PC and the robot can be programmed independently of operation. The non-productive times are reduced to an absolute minimum.

- The manipulator is fully integrated into the WeldSpace controller and mathematically coupled to the robot for synchronized movements.

Optional accessories

Torch cleaning station

Optimum and reliable cleaning of the gas nozzle ensures a reliable welding process and increases system availability

MobiAirClean D1 welding fume extraction system

The automatic cleaning system makes the mobile filter system ideal for welding work which involves non-alloy and alloyed steels, galvanised materials and aluminium and produces a high volume of fumes

Network camera

Check and document welding results by means of live transmission and videos. With autofocus and wide dynamic range, ideal for difficult lighting conditions (welding light).

Control panel terminal

Perfect storage option for the UR control panel, enabling button, Fronius panel and industrial tablet. Extra heavy design prevents tipping over and, with the brakes on each castor, the terminal stays where you need it

Subscribe to our YouTube Channel that showcases many products and example applications.

Unparalleled product benefits

Integrated and professional high-performance welding system

FRONIUS Robot welding equipment

Universal Robots UR e-Series or FANUC Cobot CRX-10iA

Either with the collaborative robot UR10e from Universal Robots or with the FANUC Cobot CRX-10iA

Central control unit

The DEMMELER WeldSpace 4.0® user interface guides you step by step to perfect welding results

Highest safety standard

Automatically moving protective enclosure with two roller shutter doors (aluminium cladding with viewing elements made of protective welding glass)

Extensive protected job library

More than 100 protected welding jobs including all important parameters tailored to the material, power source, welding process and torch – whether you're welding in the thin aluminium sheet sector or in steel construction

Two-axis manipulator

Modular two-axis manipulator with a load capacity of up to 500 kg for professional workpiece clamping and circumferential seam welding with the rotary axis

Extension set of SPACE A into SPACE A1 / A2

With this extension set, the SPACE A workspace can be divided into two workspaces – SPACE A1 and SPACE A2. This makes it possible to operate the welding cell in three-station mode

Movable gantry makes crane loading possible

Workpieces are easily loaded for set-up and reclamping, including by crane

Maximum flexibility with the equipment

Depending on your requirements, choose from the extensive equipment options of the COBOT WeldSpace 4.0®

Unique programming and operating concept

With the DEMMELER WeldSpace 4,0® Software, you can create complex welding programs intuitively without explicit programming knowledge

Download Product Brochures

COBOT WeldSpace 4.0® TABLE 24/12

Version UR & F

For more information about the DEMMELER COBOT WeldSpace 4.0® TABLE 24/12 UR & F and its equipment options, simply download the product brochures.

Contact

Get in touch!

Would you like individual advice on our products and services? Contact us and together we will find a solution.

We look forward hearing from you!