Contact

DEMMELER Maschinenbau GmbH & Co. KG

Alpenstraße 10

87751 Heimertingen

Germany

Tel: +49 (0) 8335 / 9859-0

info(at)demmeler.com

www.demmeler.com

S univerzálním 3D pracovním a svařovacím stolem lze splnit všechny požadavky, jak v horizontálním, tak i ve vertikálním rozsahu. Přesně, rychle a obratem ruky zhotovíte s tímto modulárním stavebnicovým systémem své díly: Skříně strojů, podstavce, rámy, traverzy, konzoly, zábradlí, schody, vrata, rozvaděče, plechová obložení atd. Časově náročné a cenově nákladné konvenční přípravky tak patří minulosti. S tímto systémem dosáhnete u každého obrobku rychlé a přesné nastavení a samozřejmě zafixování požadovaných rozměrů. Vaše jednotlivé svařované díly jsou během procesu stehování a svařování upnuté na příslušných plochách nebo bodech a udržují tak optimální polohu.

3D svařovací stoly

-

Welding Table PROFIPremiumLINE D28

For everyday and large welding constructions, system bores in a 50 x 50 mm grid

Price on requestplus VAT

-

Welding table PROFIPlusLINE D28

For everyday and large welding constructions, system bores in a 100 x 100 mm diagonal grid

Price on requestplus VAT

-

Welding table PROFIEcoLINE D28

For everyday and large welding constructions, system bores in a 100 x 100 mm grid

Price on requestplus VAT

-

Welding table PROFIHobbyLINE D28

For everyday and large welding constructions, system bores in a 100 x 100 mm grid

Price on requestplus VAT

-

3D measuring, assembly and adjustment table

Outstanding precision for adjusting, measuring and assembling components

Price on requestplus VAT

-

Welding table PROFIPremiumLINE D22

For light to moderate applications, system bores in a 50 × 50 mm grid

Price on requestplus VAT

-

Welding table PROFIPlusLINE D22

For light to moderate applications, system bores in a 100 × 100 mm diagonal grid

Price on requestplus VAT

-

Welding table PROFIPlusLINE D16

For delicate applications, system bores in a 50 x 50 mm diagonal grid

Price on requestplus VAT

-

Price on request

plus VAT

DemontXBlack 890

Použitím vysoce legovaného základního materiálu stolní desky v kombinaci se speciálně optimalizovaným procesem tvrzení DEMMELERdosahuje nejlepších vlastností materiálu. Kombinace z vysoce legovaného základního materiálu a speciálního procesu tvrzení umožňují nejlepší vlastnosti svařovacích stolů pro extrémní namáhání.

| DemontXBlack 890 | DemontXBlack 760 | SOLID | ||

| Zatížení | vysoká nosná zatížení | • • • • • | • • • • • | • • • • • |

| Rovinnost | pro nejlepší kvalitu obrobku | • • • • • | • • • • | • • • • • |

| Vodivost | pro nejlepší výsledky svařování při použití ukostření | • • • • | • • • • | • • • • • |

| Základní tvrdost | pro vysokou rázovou pevnost | • • • • • | • • • • | • • • |

| Povrchová tvrdost | rezistentní proti rozstřiku při svařování | • • • • • | • • • • | • • • |

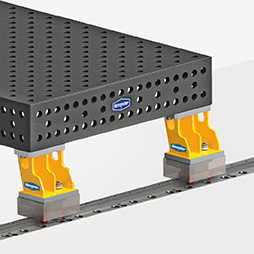

Stůl se dodává se standardní nohou. Extrémní masivní provedení se stará o nejvyšší zatížení - 3 000 kg na nohu. Manžeta nohy zabraňuje uskřípnutí a tím opotřebení balíčku hadic. Tím je možné pohodlné používání ukostření. Kromě toho chrání závitové vřeteno před znečištěním a opotřebením. Jemně nastavitelné jakož i jednoduché a stabilní upevnění.

Table of contents

- What is a welding table and what is it used for?

- What types of welding tables are there?

- What are the advantages of a welding table?

- What should I look for when buying a welding table?

- What sizes and designs are available?

- How much does a welding table cost?

- How do I properly maintain a welding table?

- What accessories are available for welding tables?

What is a welding table and what is it used for?

A welding table is a special work surface used in metalworking and manufacturing to precisely position and join workpieces. Welding tables provide the stability and flexibility required for different welding processes. The 3D welding table was invented by DEMMELER. This innovative table revolutionises the way welding work is carried out by offering three-dimensional adaptability for positioning and fixing workpieces. With its modular design, DEMMELER's 3D welding table enables efficient and precise machining of complex geometries, resulting in a significant improvement in productivity and quality.

What types of welding tables are there?

There are various types of welding tables, including:

- Modular welding tables: Flexibly expandable with extensive accessories, ideal for individual work requirements.

- Static welding tables: In fixed sizes and designs, suitable for standardised work.

- High-strength welding tables: Made from robust materials such as steel, for demanding industrial applications.

- Portable welding tables: Mobile with heavy-duty wheels, perfect for use in different locations.

- Height-adjustable welding tables: Adjustable table height (manual or electric) for an ergonomic working position

What are the advantages of a welding table?

A welding table offers numerous advantages that can improve both the efficiency and quality of welding work. Here are some of the most important advantages:

- Stability and security: A welding table is usually robust and stable, which creates a safe working environment. This reduces the risk of accidents and injuries during welding.

- Ergonomics: Welding tables are often designed to provide a comfortable working height, which reduces operator fatigue and promotes better posture.

- Flexibility: Many welding tables have adjustable or modular components that make it easy to handle different workpieces and welding positions.

- Precision: A well-designed welding table enables more precise alignment and positioning of workpieces, resulting in higher welding quality.

- Accessibility: Welding tables often provide sufficient space to keep tools and materials within reach. This improves efficiency and reduces search times.

- Easy handling of workpieces: Many welding tables are equipped with devices that make it easier to hold and secure workpieces, which makes work faster and safer.

- Heat dissipation: Welding tables are often made of materials that allow good heat dissipation, reducing the risk of deformation or fire hazard.

- Versatility: Welding tables can be used for various welding processes (e.g. MIG, TIG, electrode welding) and are often equipped with accessories that allow them to be adapted to different applications.

- Cleanliness and tidiness: A welding table helps to keep the work area organised and clean, which can increase productivity.

- Investment in quality: A high-quality welding table can extend the service life of tools and machines, as it enables gentle handling and processing of materials.

What should I look for when buying a welding table?

When purchasing a welding table, you should pay attention to the following points:

- Material quality: High-quality steel ensures durability.

- Size and work surface: Suitable for the planned workpieces and work requirements.

- Modularity: Expandability through accessories and add-ons.

- Stability and load capacity: Suitable for heavy workpieces.

- Accessory compatibility: Fixing points, rails, brackets.

- Value for money: Quality should be the main focus in order to ensure long-term satisfaction.

What sizes and designs are available?

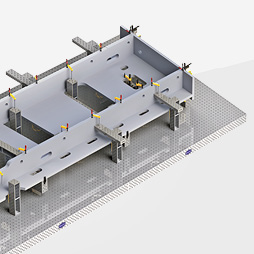

Welding tables are available in various sizes, from small table tops (e.g. 1000 x 500 mm) to standard sizes (e.g. 2000 x 1000 mm, 2400 x 1200 mm) to large work surfaces (e.g. 4000 x 2000 mm, 4800 x 2400 mm). In addition, several 3D welding tables can be connected to each other directly or with spacers. This creates one or more workstations that are precisely tailored to the workpieces to be processed. They are available in different heights, usually between 850 and 950 mm.

How much does a welding table cost?

Prices vary depending on size, material, features and manufacturer. A simple, small welding table can cost from around 500 Euro, while professional, large and modular systems can range from 1,000 to 5,000 Euro or more. It is worth investing in quality to ensure durability and safety.

How do I properly maintain a welding table?

To maximise the service life of your welding table:

- Cleaning: Regularly remove dirt, dust and spark residue, for example with a bench stone and a round brush.

- Protection against corrosion: Treat the welding table regularly with a welding table protective spray.

- Surface care: Check surfaces for damage.

- Check accessories: Check bolts and other accessories for wear.

- Storage: If not in use for a prolonged period, store in a dry place.

What accessories are available for welding tables?

The clamping devices used in welding should be suitable for a variety of clamping tasks and should also be easy to integrate and expand. DEMMELER's multifunctional tool can be combined in any way you like. This means that significantly less equipment is needed to clamp workpieces. The accessories make the welding table even more versatile:

- Patented PPC bolt: For precise fixing of workpieces thanks to polygonal spreader elements for maximum clamping force

- Spacer blocks: Whether as a frame, fixture, table extension or modular insert on the rail system

- Clamping angles: The aluminium-titanium design of the angle brackets enables optimal and very easy handling due to their low weight.

- Clamps: Constructed using round tubes, making them extremely robust and enabling maximum clamping forces to be achieved.

- Table accessoires: With accessories from DEMMELER, your workplace will always be perfectly organised.